Description

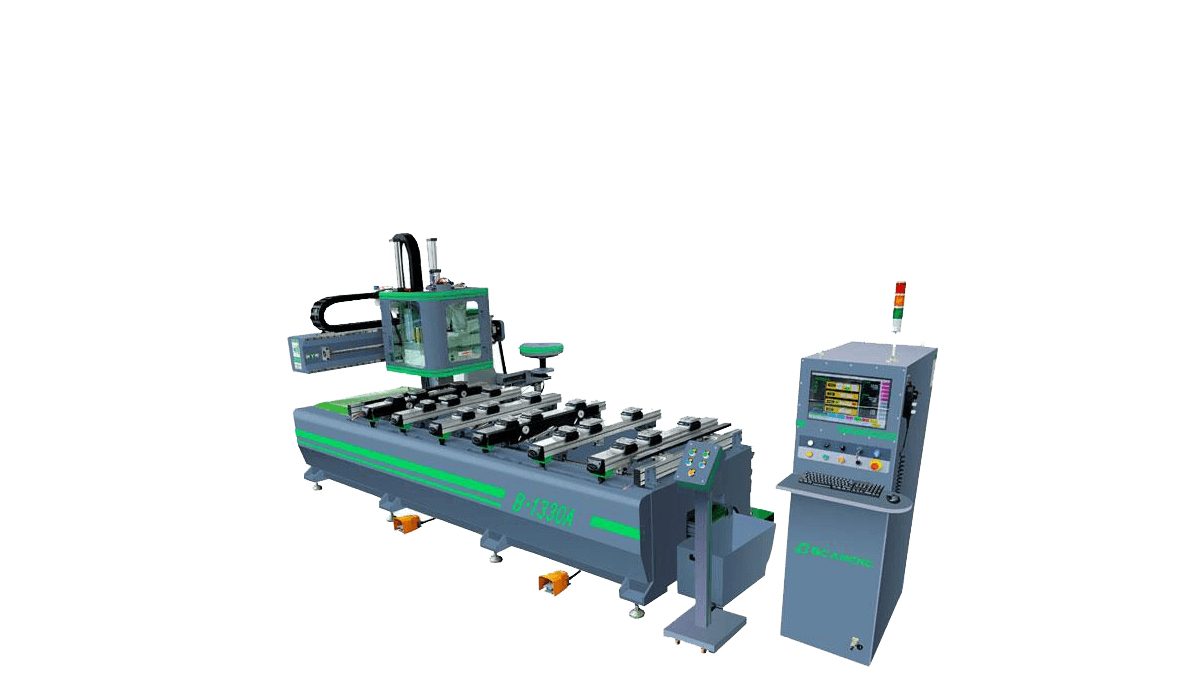

PTP woodworking engraving machine is a CNC machine specially designed for plate processing, using German Schmalz PTP table, especially suitable for furniture manufacturing industry. PTP cnc router machine can move accurately from one point to another to perform operations such as drilling, grooving and engraving.

This type of engraving machine is usually equipped with an automatic tool change system and multiple rows of drill bits. It can efficiently handle the production of panel furniture such as cabinets and wardrobes, improve processing speed and accuracy, reduce manual intervention, and is very suitable for mass customized production.

Features

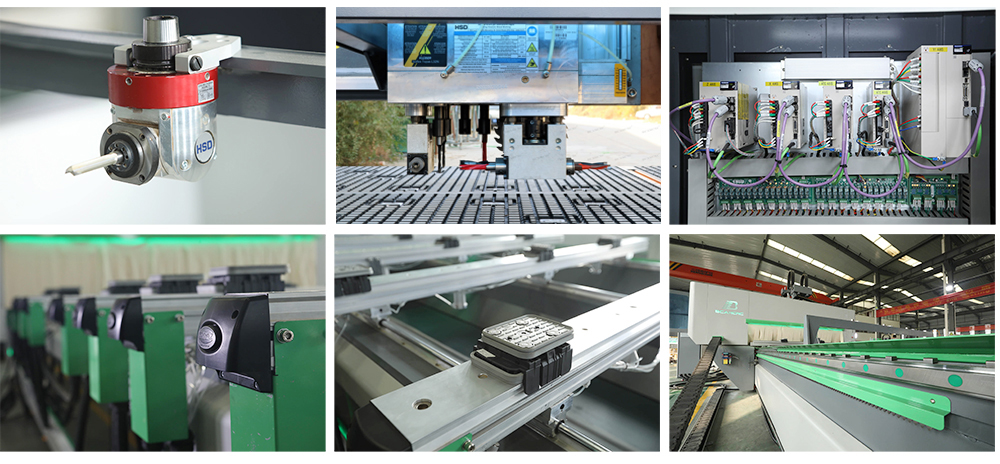

1. ISO 30 or HSK F63 electrospindle, 13.2 kW AND Boring Head 9+3+1 are designed and manufactured for BCAM by Italy HSD

2. Pod and Rail Vacuum table It is divided in 2 work zones.This machine is mainly used to make solid wood door or for panel processing , Eesy to Loading and Unloading

3. Automatic Tool Change: BCM1325F series is a cnc router designed by BCAM for Carousel tools changer 8 Tools or more upon request.

4. This aluminum protrusion located at the end of the machine helps the operator to slide the workpiece on with ease.

5. Spindle and Drilling System: BCM1325F selects Italian HSD air-cooled spindle, power range:9.5KW-15KW.high-power and high-speed spindles for optimum processing of rigid sheet materials.

PTP cnc router drill bit

PRODUCTS VIDEO

5 axis wood working PTP machine, Multi-purpose machining center, suitable for processing various molds and wood products with high added value and high precision requirementsTechnical Parameters

MODEL | BCM-F series |

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft |

Optional Working Area | 1300*1300*200mm|4*4ft |

Optional Working Area | 1500*3000*200mm|5*10ft |

| Spindle Power | 9.5kw ltaly air cooling spindle(Optional :11kw 13kw) |

X,Y,Z Traveling Positioning Accuracy | +0.01/2000mm |

Table Surface | Vacuum + Pop-up Pins Table |

X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBl Ball Screw |

Max. Rapid Travel Rate | 50m/min |

Max. Working speed | 40m/min |

Cutting thickness | According materials |

Spindle Speed | 6000-24000RPM |

Drive Motors | Japanese askawa Servo motor and Drivers |

Working Voltage | AC380v/50HZ/3 phase |

Command Language | G Code, M Code |

Operating System | Taiwan Syntec control system |

Interface | USB.NETWORK.WIFI |

Software Compatibility | Option:Alphacam/solidworks/AutoCAD.etc |

Running Environment | Temperature:0'C~45'℃ Relative Humidity:30%~75% |

Download Zone

More downloadsApplication industry

Kitchen appliances,sheet metal case cabinets,machinery equipment,electrical equipment,lighting hardware,advertising signs,auto parts,display equipment,various metal products,sheet metal cutting and processing industries.