Description

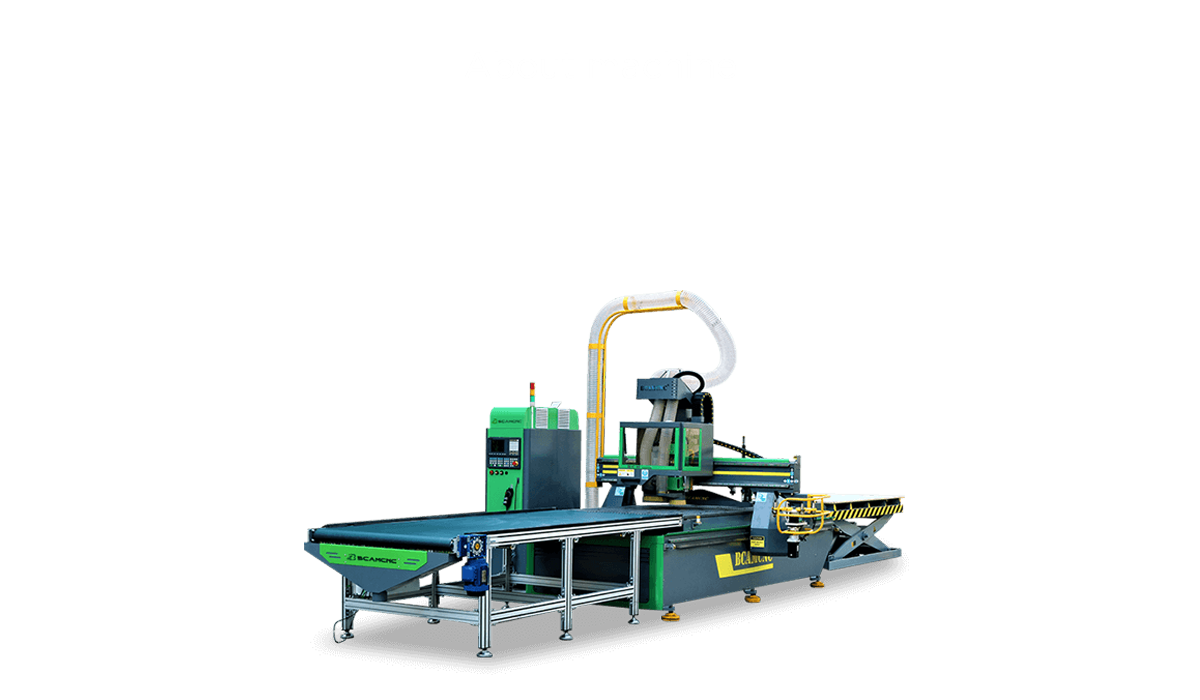

E series cnc router furniture making machine features automatic loading panel lift system, automatic advance unloading transfer table, very strong welded steel beam frame with rotary tool changer on gantry, 13 HP router spindle and 9 spindle drill.

The automatic loading and unloading woodworking engraving machine is a CNC equipment with integrated automation technology. The automatic loading and unloading function greatly improves production efficiency, reduces labor costs, and also increases production safety and continuity. It is particularly suitable for large-scale furniture manufacturing and wood products processing industries.

Features

1. Panel Loading system with scissor lift and automatic panel alignment. The system ease of use ensures long term reliability .also Moving the panel with dynamic vacuum sunction cup loading system , A solution that adats to all sureface types.

2. BCM1325E series is a cnc router designed by BCAM for automatic disc changer. This series is more automatic than BCM1325A manual tool change series. It is faster than BCM1325C series tool change, eliminating manual The cumbersome tool change shortens the tool change time and makes the cnc router more precise.

3. BCM1325E selects Italian HSD air-cooled spindle ES951 9.5KW . Choose from manual, quick-release, high-power and high-speed spindles for optimum processing of rigid sheet materials.

CNC Router Details

The base of the machine is a 6000 pound very heavy duty welded steel beam floor model frame. The phenolic vacuum table is then mounted to the steel frame for an excellent working surface and comes with an MDF spoilboard machined at the factory and bolted down to the table.

We use plastic bolts to ensure no damage to cutters from contact. The spoilboard is bolted to the table to ensure stability during the loading and unloading process.

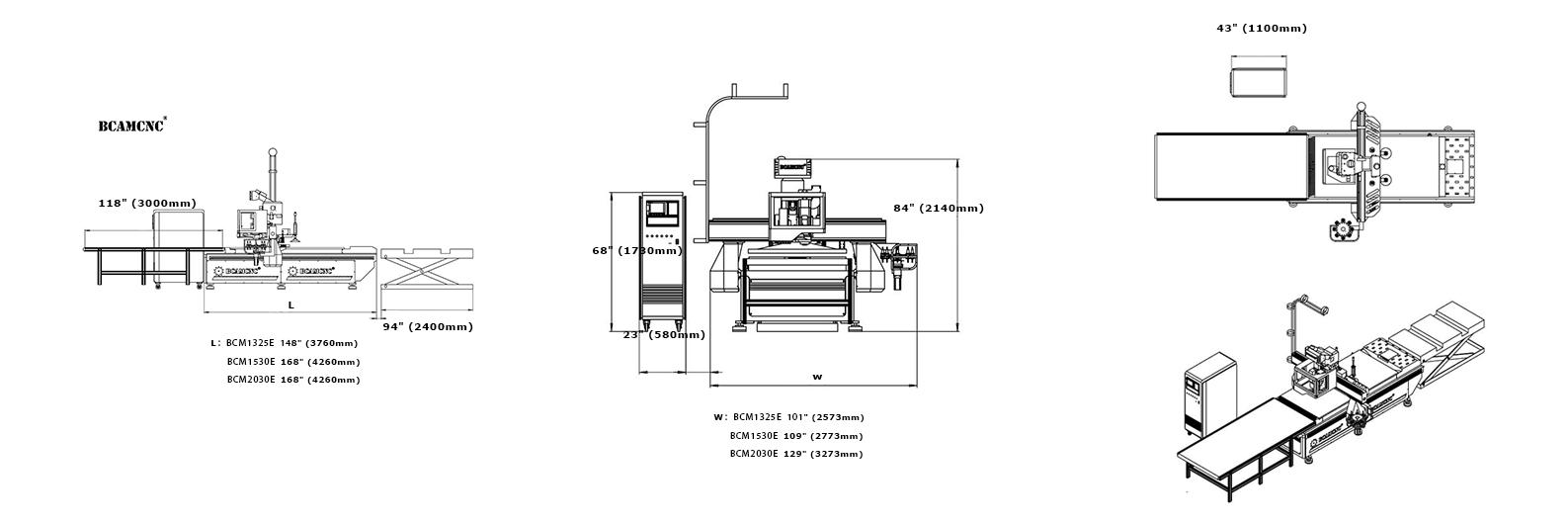

Design drawings

PRODUCTS VIDEO

BCAMCNC automatic load cnc router with edgebanding machine connect Line, Full automatic cabinet produce LineTechnical Parameters

MODEL | BCM-E series |

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft |

Optional Working Area | 1300*1300*200mm|4*4ft |

Optional Working Area | 1500*3000*200mm|5*10ft |

Optional Working Area | 2000*3000*200mm|7*10ft |

| Spindle Power | 9kw ltaly HSD air cooling spindle |

X,Y,Z Traveling Positioning Accuracy | +0.01/2000mm |

Table Surface | Vacuum table |

X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBl Ball Screw |

Max. Rapid Travel Rate | 80m/min |

Max. Working speed | 45m/min |

Cutting thickness | According materials |

Spindle Speed | 24000r/min |

Drive Motors | 4 sets 750w Yaskawa servo motor and drivers |

Working Voltage | AC380v/50HZ/3 phase |

Command Language | G Code |

Operating System | Taiwan Syntec 6MB control system |

Interface | USB,NETWORK |

Software Compatibility | Option:Alpacam/carbinets Version/BCAMNESTTING/Solidworks.etc. |

Running Environment | Temperature:0'45'℃ Relative Humidity: 30%~75% |

Download Zone

More downloadsApplication industry

Kitchen appliances,sheet metal case cabinets,machinery equipment,electrical equipment,lighting hardware,advertising signs,auto parts,display equipment,various metal products,sheet metal cutting and processing industries.