Description

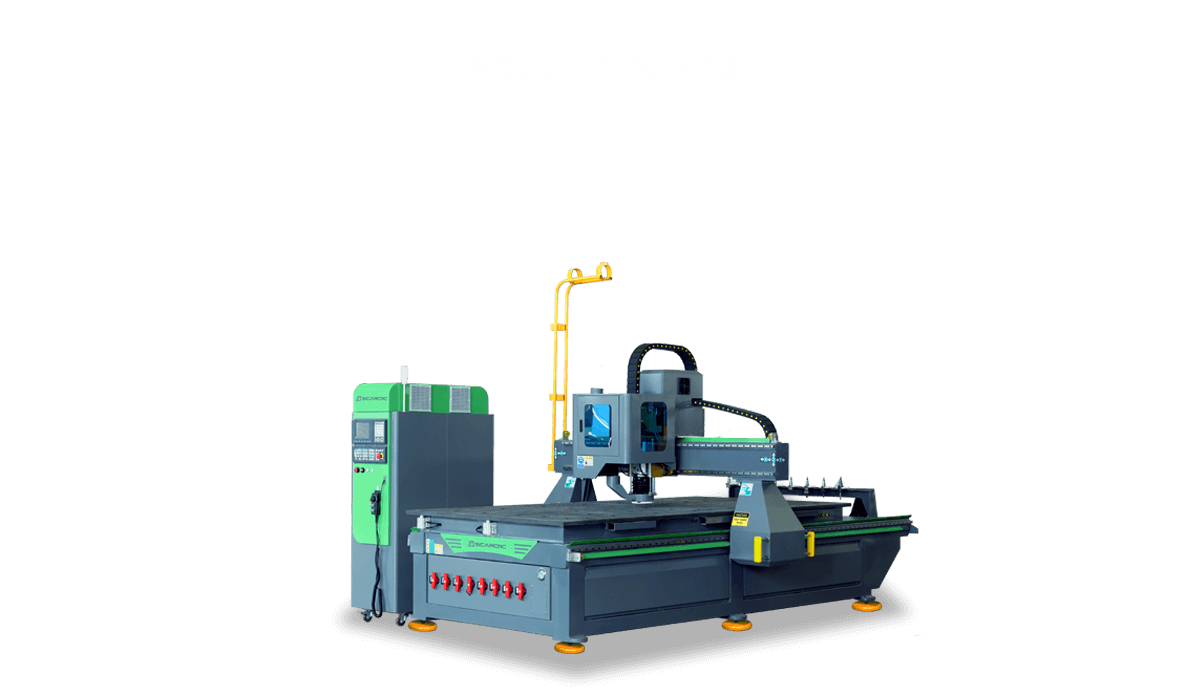

The linear inline tool change woodworking engraving machine is an efficient CNC equipment that realizes fast automatic tool change through a linearly arranged tool magazine, which can complete different processes in a short time and adapt to the processing needs of complex wood workpieces. Equipped with a powerful spindle and precision guide rail system to ensure processing accuracy and stability, it is suitable for furniture manufacturing, decorative carving and other fields, simplifying the process while improving production efficiency

This woodworking cnc router machine combines craftsmanship and intelligent CNC technology, is equipped with an efficient linear tool magazine, and is carefully crafted with high-quality accessories to ensure that every processing shows excellent accuracy and stability.

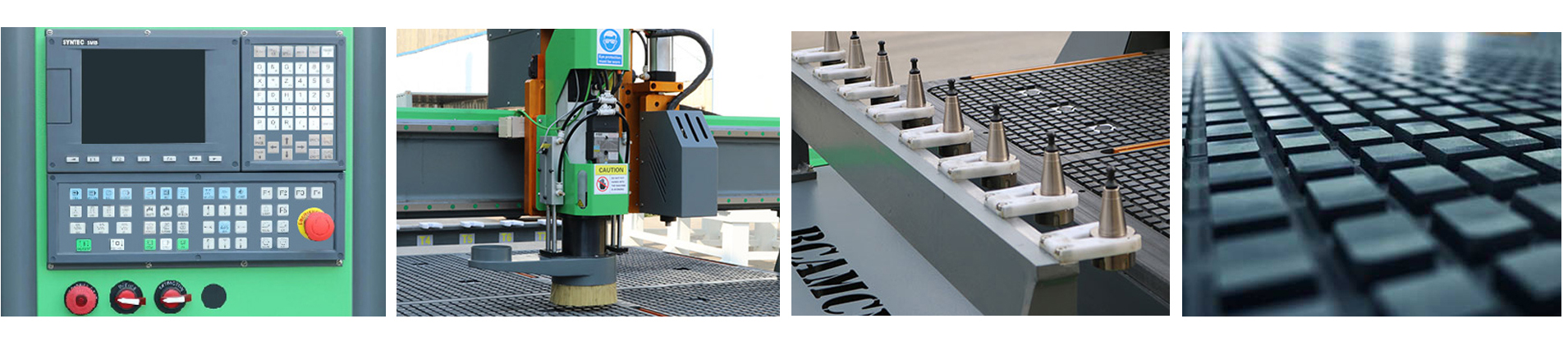

CNC Wood Router Details

1. Syntec 60W-E controller—enabling this product to accomplish multi-layer 3D job, cutting, engraving, milling, all at ease.

2. Italian HSD ES951 9.5KW(12HP) Electrospindle with 8-position Automatic Tool Changer(ISO30).

3. Unique auto tool changer system can change tools alternatively, tool sensor to compensate the tolerance of tool length.

4. Vacuum table using high-density (1.3-1.45g/cm) material with great suction strength, comfortably accommodating all sizes of work piece.

5. The country's first dust-free vacuum system is inspired by the “Typhoon” cyclone. Our French engineer, Mr Ness, studied this technology for three years and finally developed it successfully which has been perfectly applied into our products

6. World-class Japan Yaskawa servo motor and driving system ensures machine to run with fast speed and low noise.

7. Auto lubricating system, one touch can finish periodic maintenance easily.

8. The original active protection system, also known as the “anticollision emergency stop switch”, has active protection for workers’ safety during the working process of the machine.

CNC Router Machines: Revolutionizing Precision Manufacturing

The CNC router machine has become a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and versatility across industries.

As automation reshapes production workflows, these advanced systems bridge the gap between digital design and physical output,

enabling businesses to achieve complex cuts, engravings, and 3D machining with minimal human intervention.

This article explores the transformative role of CNC router machines, their applications, and key considerations for optimizing their use.

What Is a CNC Router Machine?

A CNC (Computer Numerical Control) router machine is a computer-controlled cutting tool designed to carve, mill,

and shape materials such as wood, plastics, metals, and composites. Unlike manual routers,

CNC routers follow pre-programmed designs generated via CAD/CAM software, ensuring millimeter-perfect accuracy.

These machines feature a spindle, worktable, and multi-axis movement, allowing them to execute intricate patterns at high speeds.

From prototyping to mass production, CNC router machines streamline workflows while reducing material waste and labor costs.

Applications Across Industries

The adaptability of CNC router machines makes them indispensable in diverse sectors:

Woodworking: Furniture manufacturers rely on CNC routers for carving decorative elements, cutting joints, and producing cabinetry components.

Aerospace: High-precision parts, such as turbine blades and structural components, are machined from lightweight alloys.

Signage and Advertising: Acrylic, foam, and aluminum signs are crafted with intricate lettering and logos.

Automotive: Custom molds, dashboards, and interior trim pieces are produced efficiently.

DIY and Prototyping: Hobbyists and engineers use desktop CNC routers to bring digital designs to life.

By automating repetitive tasks, CNC router machines enhance productivity while maintaining consistency—

a critical factor in industries like aerospace and medical device manufacturing, where even minor errors can have severe consequences.

Advantages of CNC Router Machines

Investing in a CNC router machine offers several competitive advantages:

Precision: Tolerances as tight as ±0.005 inches ensure flawless replication of complex designs.

Speed: Multi-axis movement and high RPM spindles reduce cycle times by up to 70% compared to manual methods.

Material Versatility: Compatible with metals, plastics, ceramics, and composites, these machines support cross-industry applications.

Scalability: Once a design is programmed, CNC routers can produce thousands of identical parts with zero deviation.

Cost Efficiency: Reduced labor expenses and material waste translate to higher profit margins.

For businesses seeking to modernize their operations, integrating a CNC router machine is a strategic move toward lean manufacturing.

Choosing the Right CNC Router Machine

Selecting an optimal CNC router machine requires evaluating several factors:

Work Area Size: Larger machines accommodate bigger materials but require more floor space.

Spindle Power: Higher horsepower (e.g., 5–15 HP) enables cutting denser materials like steel.

Software Compatibility: Ensure compatibility with industry-standard CAD/CAM programs like AutoCAD or Fusion 360.

Automation Features: Look for tool changers, vacuum tables, and dust collection systems to minimize downtime.

For example, a furniture workshop might prioritize a 4' x 8' CNC router with a 10 HP spindle for processing hardwood sheets,

whereas a metal fabrication plant may opt for a gantry-style machine with coolant systems.

Maintenance and Optimization Tips

To maximize the lifespan of a CNC router machine, adopt these best practices:

Regularly lubricate rails and ball screws to prevent wear.

Calibrate the machine monthly to maintain accuracy.

Use sharp, high-quality cutting tools to reduce spindle strain.

Implement predictive maintenance software to monitor component health.

Additionally, training operators in G-code programming and machine troubleshooting minimizes operational hiccups.

The Future of CNC Router Technology

Emerging trends such as AI-driven predictive maintenance, IoT-enabled machine monitoring,

and hybrid additive-subtractive manufacturing are pushing CNC router machines to new heights.

For instance, some systems now integrate 3D scanning to reverse-engineer parts or self-correct toolpaths in real time.

As sustainability gains traction, energy-efficient models with recyclable components are also entering the market.

Conclusion

The CNC router machine stands as a testament to the synergy between human ingenuity and technological advancement.

By delivering precision, speed, and adaptability, it empowers industries to innovate while staying competitive.

Whether for crafting bespoke furniture or aerospace components, investing in a CNC router machine is not just about adopting a tool—it’s about embracing the future of manufacturing.

Design drawings

PRODUCTS VIDEO

1300*2500mm 1500*3000mm 2000*3000mm 2100*3100mm working area cnc machine with Liner type auto tool magazine 8-12 pcs Tools ISO30/HSK F63Technical Parameters

MODEL | BCM-C series |

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft |

Optional Working Area | 1300*1300*200mm|4*4ft |

Optional Working Area | 1500*3000*200mm|5*10ft |

Optional Working Area | 2000*3000*200mm|6*10ft |

Optional Working Area | 2000*4000*200mm|6*13ft |

Optional working Area | 2000*6000*200mm|6*20ft |

Spindle Power | ES951 9.5kw ltaly HSD air cooling spindle |

X,Y,Z Traveling Positioning Accuracy | +0.01/2000mm |

Table Surface | Vacuum table+Intergrated T-solt table clamping System |

X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBl Ball Screw |

Max. Rapid Travel Rate | 90m/min |

Max. Working speed | 60m/min |

Cutting thickness | According materials |

Spindle Speed | 6000-24000RPM |

Drive Motors | Japanese Yaskawa Servo Drive System |

Working Voltage | AC380v/50HZ/3 phase |

Command Language | G Code |

Operating System | Taiwan Syntec 6MB control system |

Interface | USB |

Software Compatibility | Option:Type3/Ucancam/Alphacam/Aspire/Solidworks,etc |

Running Environment | Temperature:0'C~45'C Relative Humidity: 30%~75% |

Download Zone

More downloadsApplication industry

Kitchen appliances,sheet metal case cabinets,machinery equipment,electrical equipment,lighting hardware,advertising signs,auto parts,display equipment,various metal products,sheet metal cutting and processing industries.